The Rise of Chinese CNC Routers: Transforming the Manufacturing Landscape

In the ever-evolving world of manufacturing, technology plays a crucial role in determining productivity, efficiency, and cost-effectiveness. One of the standout innovations that have reshaped the landscape of industrial manufacturing is the Chinese CNC router. These machines have not only made it easier for businesses to achieve precision and excellence in their production processes but have also opened new avenues for creativity and design. This article delves into the multifaceted benefits of CNC machines for sale, particularly focusing on the Chinese CNC router market and how they facilitate growth and innovation.

Understanding Chinese CNC Routers

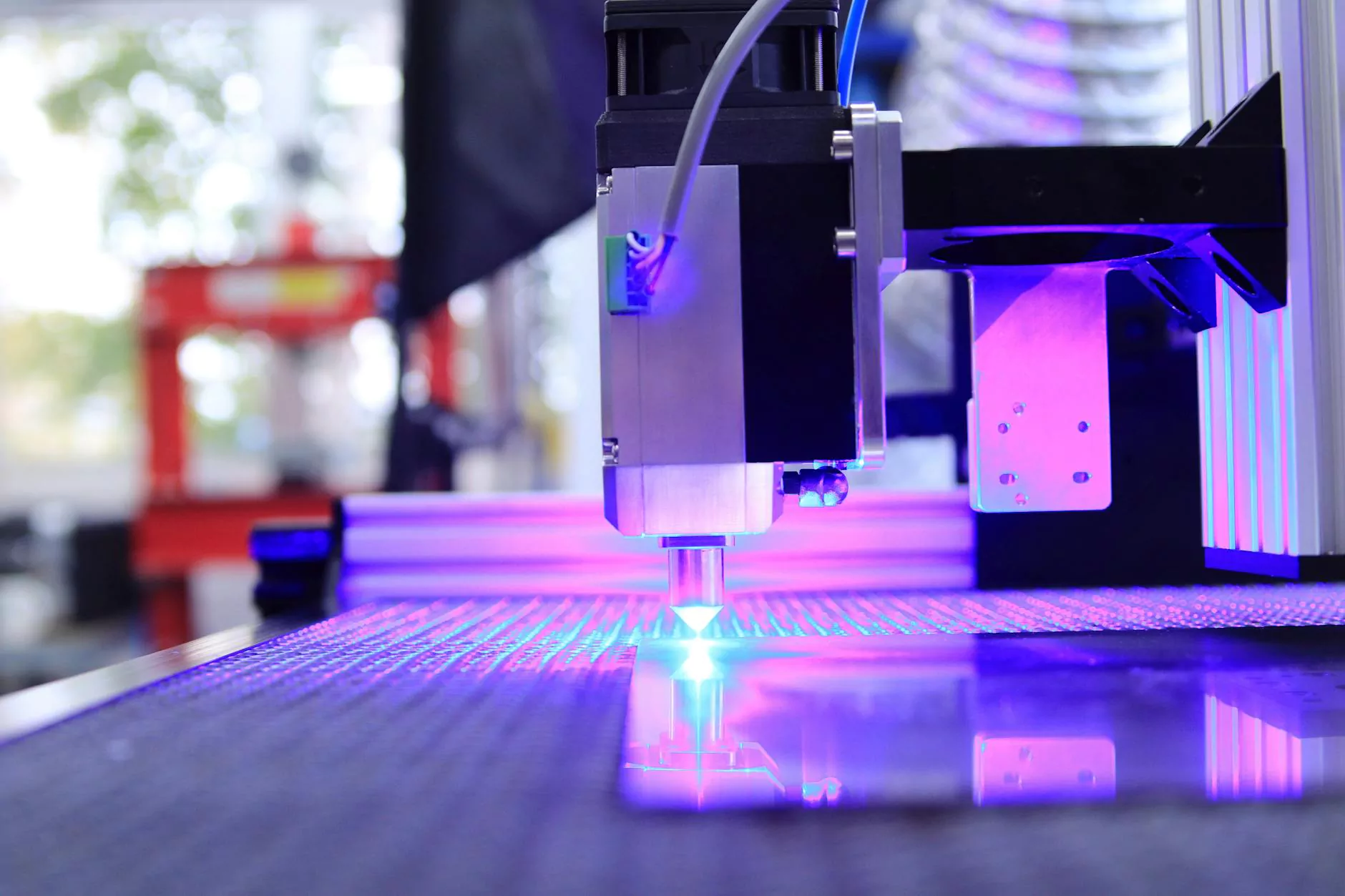

A CNC (Computer Numerical Control) router is a machine used for cutting materials such as wood, plastic, metal, and composites. The Chinese CNC router has become increasingly popular due to its affordability, versatility, and the availability of advanced technologies. Unlike traditional routers, CNC routers operate under computer control, which means they can operate continuously with high accuracy over extended periods.

Key Features of Chinese CNC Routers

- High Precision: The precision of Chinese CNC routers allows manufacturers to produce intricate designs with exact specifications.

- Material Versatility: These routers can handle a wide variety of materials, making them an ideal choice for diverse industries.

- User-Friendly Software: With easy-to-use software interfaces, operators can design and execute complex projects with minimal effort.

- Cost-Effectiveness: Compared to other CNC machines, the Chinese CNC router offers high value at a lower price point, making it accessible for small to medium-sized enterprises.

- Customizable Options: Many manufacturers provide customizable features tailored to specific needs, enhancing operational efficiency.

The Role of Chinese CNC Routers in Modern Manufacturing

As businesses seek to optimize their production processes, the demand for advanced machining tools has surged. The Chinese CNC router has emerged as a game-changer in the manufacturing sector, and here are some reasons why:

1. Increased Efficiency and Production Speed

One of the primary advantages of Chinese CNC routers is their ability to operate at remarkable speeds without compromising on quality. Traditional machining methods often involve manual setups which can be time-consuming. With CNC technology, once a design is programmed, the router can perform repetitive tasks fast and efficiently. This is particularly vital for high-volume productions.

2. Precision Engineering

In industries where precision is paramount, such as aerospace, automotive, and electronics, the accuracy of Chinese CNC routers is unmatched. The digital nature of these machines means that even the most complex geometries can be replicated with consistency—thus reducing waste and minimizing the errors typically associated with manual labor.

3. Enhanced Creative Possibilities

The versatility of CNC machines for sale also fosters creativity in product design. Designers can experiment with unconventional materials and complex shapes, previously deemed impossible to fabricate. The ability to create intricate patterns and fine details has opened new avenues in fields such as architecture, signmaking, and art installations.

Factors Contributing to the Popularity of Chinese CNC Routers

The rise of the Chinese CNC router can be attributed to several interrelated factors:

1. Technological Advancements

China has invested heavily in research and development in the CNC technology sector. Innovations in cutting tools, automation, and software have made Chinese CNC routers not only more reliable but also capable of integrating with Industry 4.0 technologies, such as IoT and smart manufacturing systems.

2. Global Supply Chain Integration

Chinese production has established robust supply chains that enable rapid delivery and fulfillment of orders worldwide. The vast number of manufacturers ensures that companies can find a CNC machine for sale that meets their budgetary constraints and operational needs.

3. Growing Demand for Customization

As consumer preferences shift towards personalized products, businesses have had to adapt their production processes. Chinese CNC routers provide a flexible manufacturing solution that allows for high levels of customization without significantly increasing costs.

Applications of Chinese CNC Routers Across Industries

From woodworking to electronics, the applications of Chinese CNC routers are vast and varied:

1. Woodworking

The woodworking industry has embraced CNC technology to enhance productivity. Chinese CNC routers are used for cutting, engraving, and shaping wood to create intricate designs for furniture, cabinetry, and flooring.

2. Metal Fabrication

In metalworking, CNC routers can be used for plasma cutting, which is essential for creating parts for machinery, automotive components, and artistic metalwork.

3. Signmaking

The signmaking industry leverages CNC routers to produce detailed signage with varying materials, such as acrylics, wood, and metals. This technology allows for fast turnover and the ability to handle custom orders efficiently.

4. Prototyping and Model Making

Rapid prototyping is a crucial part of product development. Chinese CNC routers facilitate the fast production of prototypes, enabling companies to test and refine designs quickly, ultimately shortening time-to-market for new products.

Considerations When Purchasing a Chinese CNC Router

When exploring options for a CNC machine for sale, various factors should be considered to ensure the right fit for your operations:

1. Machine Specifications

Understanding the specific requirements of your projects is critical. Consider factors such as the size of the working area, the types of materials you intend to work with, and the precision needed for your applications.

2. Software Compatibility

The software used to program the CNC router is just as important as the machinery itself. Ensure that the controller and software are user-friendly and capable of handling the designs you plan to implement.

3. Manufacturer Reputation

Research the manufacturers and suppliers of Chinese CNC routers. Look for reviews, testimonials, and case studies that illustrate their reliability, customer service, and product quality.

4. Cost and Warranty Considerations

While Chinese CNC routers are known for being cost-effective, it’s essential to evaluate the overall cost, including maintenance, operating expenses, and any additional software or tooling that may be required. A good warranty can provide peace of mind and protect against potential issues.

Future Trends in Chinese CNC Technology

As the manufacturing sector evolves, so do the capabilities of Chinese CNC routers. Some of the anticipated trends include:

1. Automation and Integration

With the rise of smart manufacturing, expect more integration of CNC routers with automation technologies, resulting in completely automated production lines that increase efficiency and reduce labor costs.

2. Sustainable Manufacturing Practices

There is an increasing emphasis on sustainability in manufacturing processes. Chinese CNC routers will likely evolve to minimize waste, improve energy efficiency, and use eco-friendly materials.

3. Enhanced User Experience through AI

The incorporation of artificial intelligence in CNC machinery will help automate design processes and predictive maintenance, allowing machines to become even more user-friendly and efficient.

Conclusion

In conclusion, the Chinese CNC router is not just a passing trend but a cornerstone of modern manufacturing. Businesses leveraging these machines gain a competitive edge through improved efficiency, quality, and design capabilities. As technology continues to develop, it will be fascinating to witness the further innovations within this space. Investing in CNC machines for sale from reputable suppliers is critical for businesses looking to thrive in today’s dynamic market.

For manufacturers seeking a powerful yet affordable solution, the Chinese CNC router is a clear contender; it embodies the future of manufacturing, enhancing methods and approaches that lead to increased success in the competitive business landscape.

To explore a wide range of options, visit us at roc-tech.com to find the best solutions tailored to your manufacturing needs.